leak-tightness

of syringes

SCOPE

A typical syringe consists of two main parts: a barrel that holds the medication and a plunger that fits into the barrel to draw in or expel the medication from the syringe. The plunger tip, usually made of rubber, creates a seal between the plunger and the barrel to prevent medication leakage during injection.

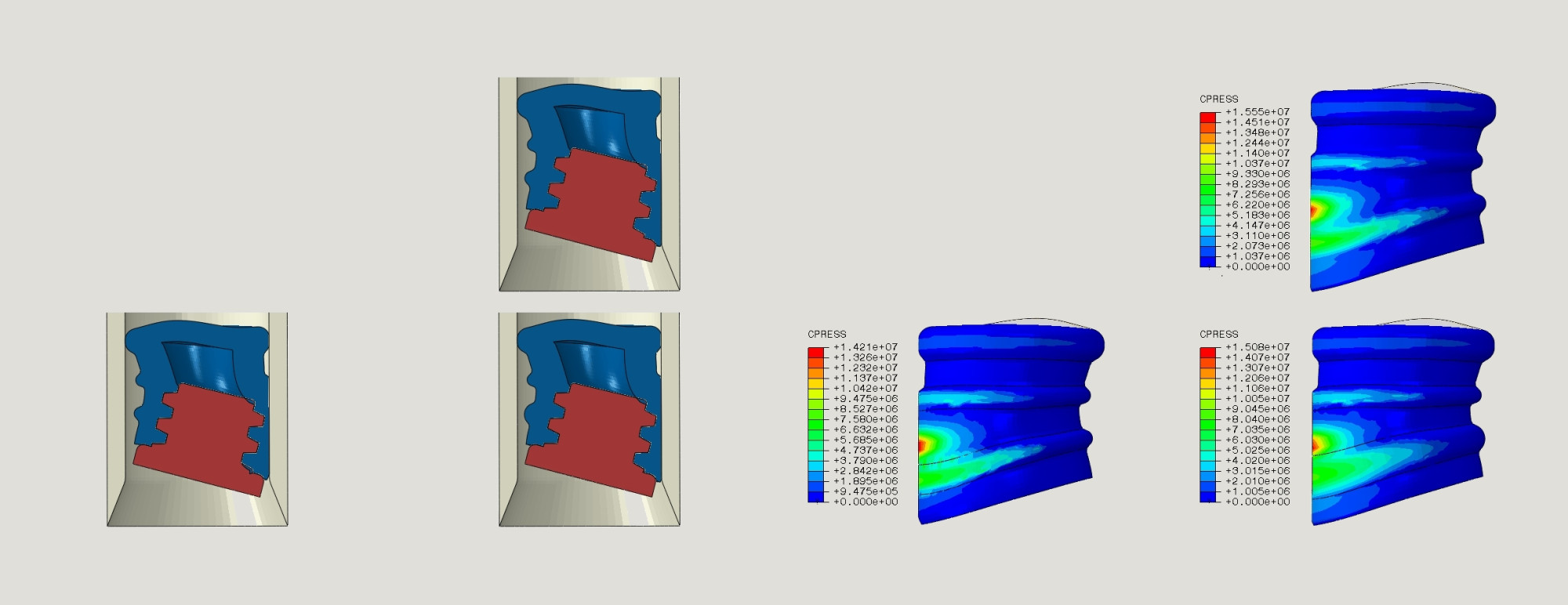

However, in daily practice, it has been observed that patients who self-administer insulin, for example, tend to insert the plunger at an angle of up to 15 degrees, causing the rubber to deform asymmetrically. This can increase the risk of medication leakage during injection.

This study investigated three commonly used syringes to assess their leak-tightness under different angles of insertion. The goal was to propose design changes for the rubber tip to increase seal efficiency while ensuring that the force required to activate the syringe remained within an acceptable range.

APPROACH

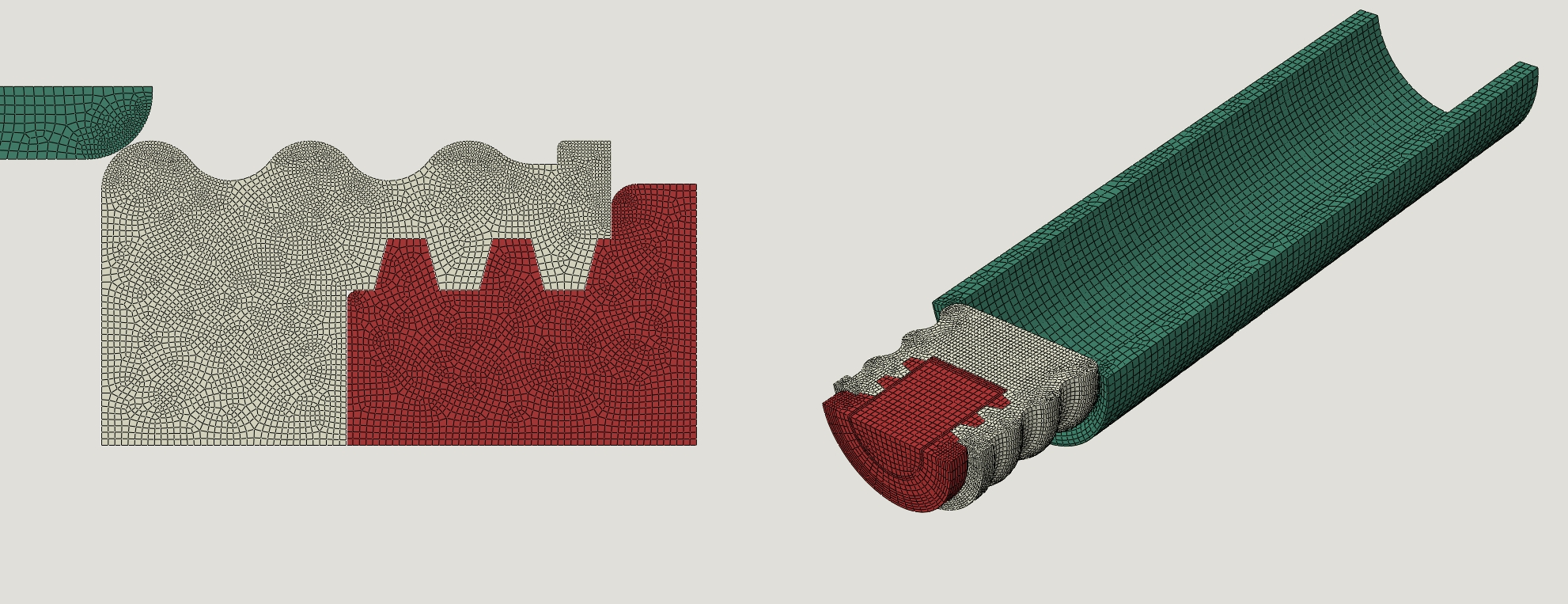

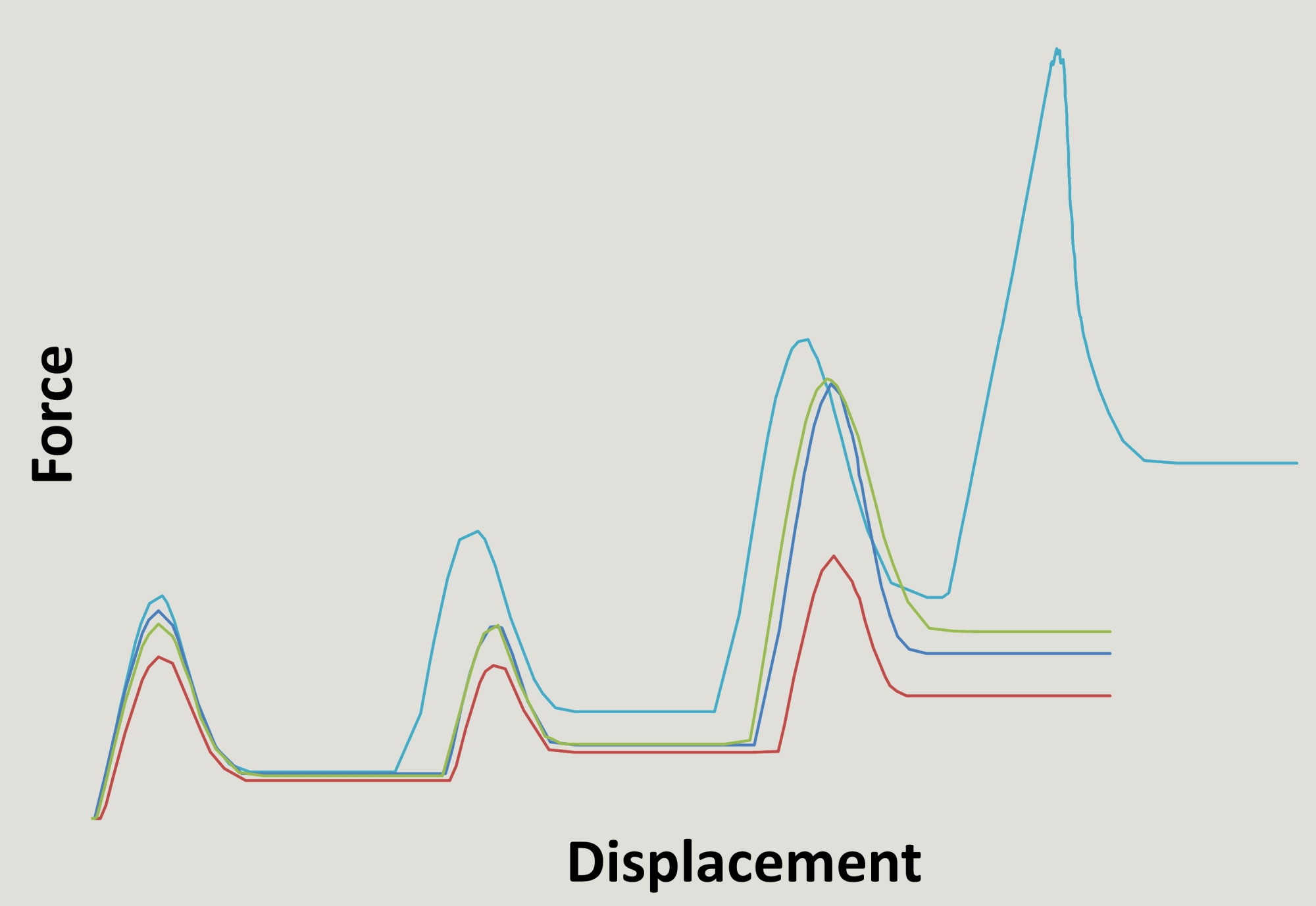

First, the rubber tips were tested under tension and compression to calibrate hyperelastic material models. Next, finite element (FE) models were developed for the existing syringes to calibrate the frictional conditions. Tests were then conducted on the syringes to determine the activation and gliding forces, which were used in the FE simulations to iteratively determine the static and dynamic friction coefficients.

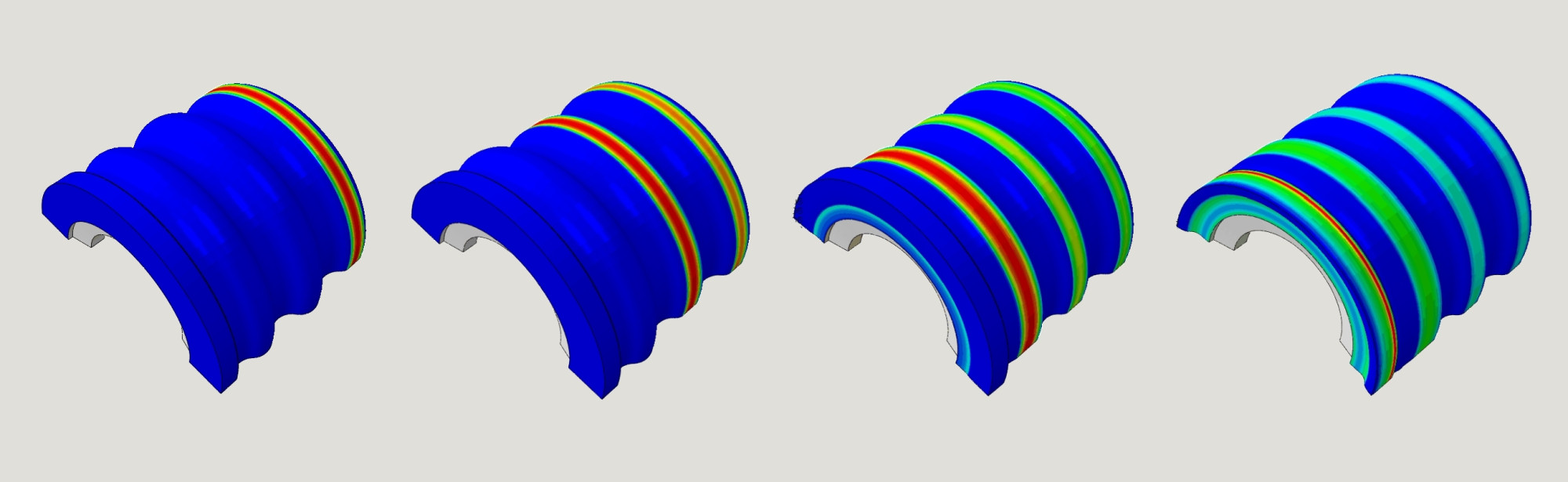

The calibrated FE models were then used to analyze the leak-tightness of the existing syringes when the plunger was driven into the barrel at different angles. By analyzing the contact pressure on the various threads of the rubber tip, the existing syringes were classified from best to worst.

RESULTS

Proposed design changes to the rubber tip were found to significantly improve leak-tightness while keeping the activation force within acceptable levels (between 5 and 10N). These changes included small geometric modifications to the rubber tip.

Meshed model of a syringe showing the barrel, plunger and rubber plunger tip

Evolution of contact pressure on the plunger tip as it is inserted into the barrel

Deformation of the plunger tip when inserted at a 15-degree angle into the barrel for three different types of syringe

Force-displacement curves for the typical insertion of the plunger into the barrel, with the peaks corresponding to the entering of a thread into the barrel