liquid-filled

sea containers

SCOPE

Following the transport of sea containers loaded with flexible tanks containing latex, it has been observed that the sidewalls of the containers are sometimes permanently deformed or bulging. It is believed that this may be due to the filling process of the tanks or subsequent transportation of the containers by trailer, particularly as the majority of these issues occurred at a site where trailers lacking shock absorbers were utilized. In response, we were tasked with conducting both static and dynamic simulations of these containers filled with liquid to confirm these hypotheses.

APPROACH

To begin the project, we conducted in-situ tests at the designated site, which involved testing two sea containers that were loaded with a 24 m3 flexible tank filled with liquid latex and driven by two different drivers. We measured the accelerations using two accelerometers that had a sample rate of 1 kHz and were mounted into a steel box connected to the container with straps, as shown in the accompanying figure. After filtering the measurements, they served as input for a dynamic analysis of the container.

We conducted two types of analyses: quasi-static and dynamic. The quasi-static analyses were performed to investigate the influence of different container wall configurations, flexible tank sizes, and liquid densities under both permanent lateral acceleration (caused by taking a turn) and no movement conditions after the filling process was complete.

Meanwhile, the dynamic analyses used the measured accelerations to assess the influence of rapidly changing accelerations during road transport. On-site measurements showed that the maximum measured values were approximately 1 g in the lateral direction and 0.75 g to 2.5 g in the vertical direction, depending on the driver. Typically, the lateral acceleration varied between 1 g and -1 g in a timeframe of 10 ms, while the vertical accelerations varied between 2.5 g and 0.75 g in a timeframe of 5 ms for driver 1 and 10 ms for driver 2.

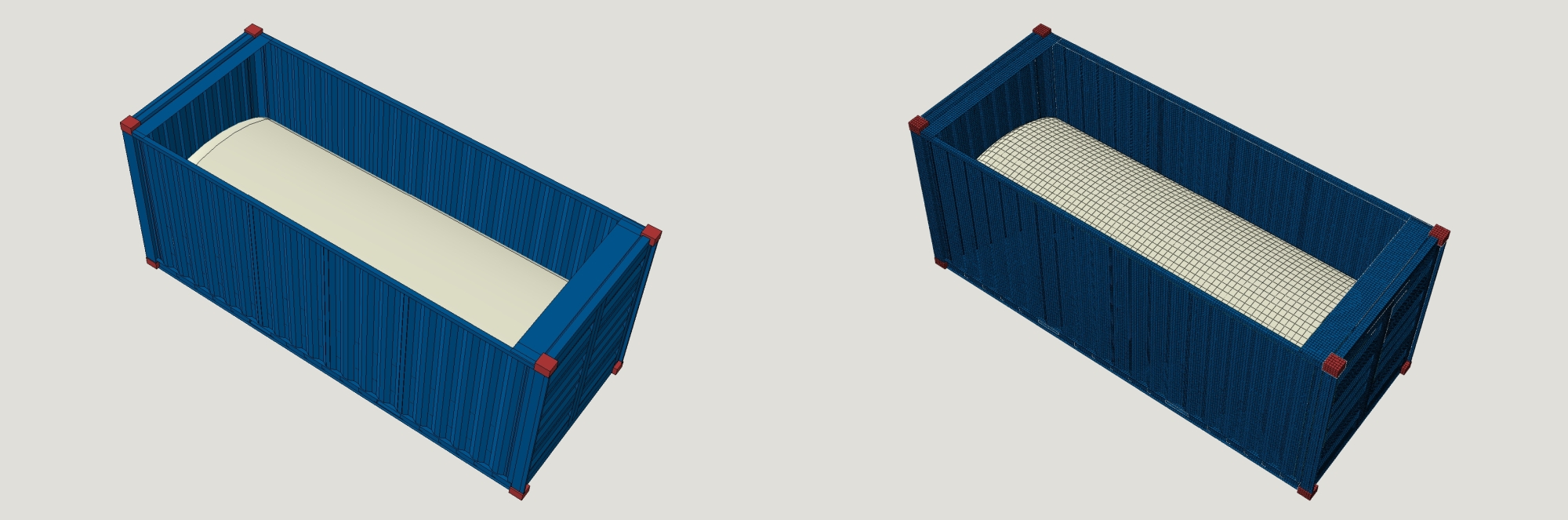

In the dynamic analysis, the effect of the medium viscosity was taken into account by performing a coupled Eulerian-Lagrangian analysis, with the latex modeled using an equation of state. The container itself was mainly modeled as shells.

RESULT

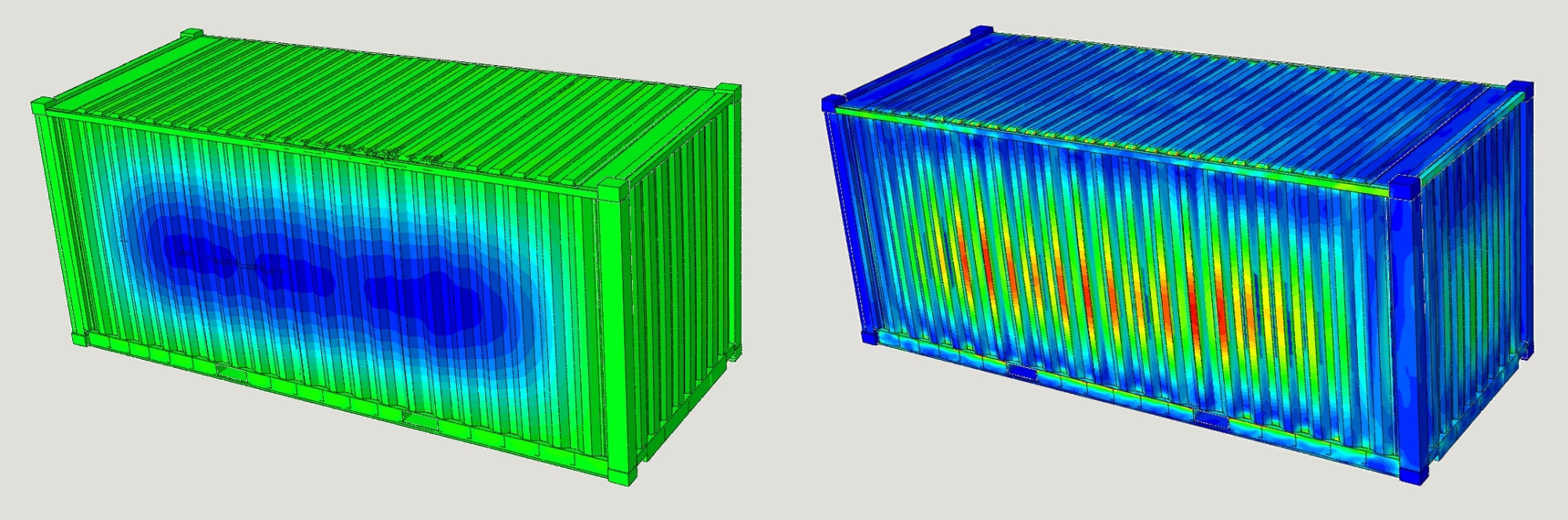

Based on the simulations conducted, it was determined that the filling of the flexible tanks does not result in any permanent deformation, except in situations where large tanks are paired with containers that have low wall thicknesses. However, when lateral accelerations are applied to the container during transport, minor plastic yielding may occur, causing some permanent deformation. This deformation is minimal, usually only a few percent at most, and the container can still safely handle the load.

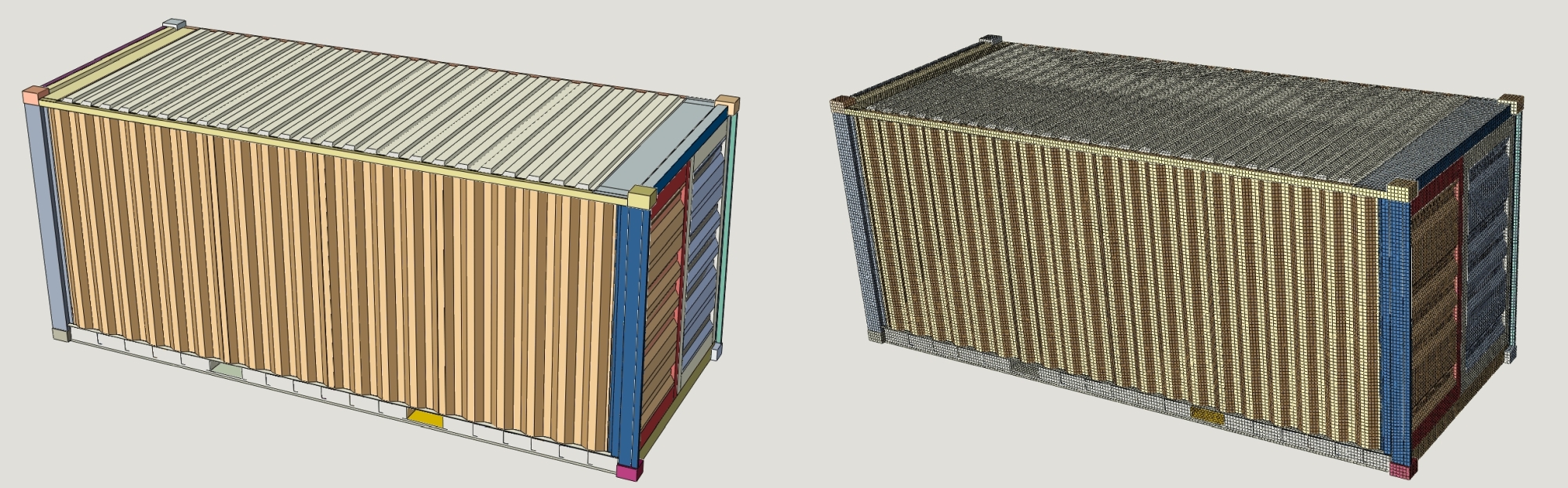

FE geometry and mesh of the sea container

Inside view of the container showing the flexible tank containing latex

Typical deformation and stress plot during the dynamic analysis