failure of a

stirring axis

SCOPE

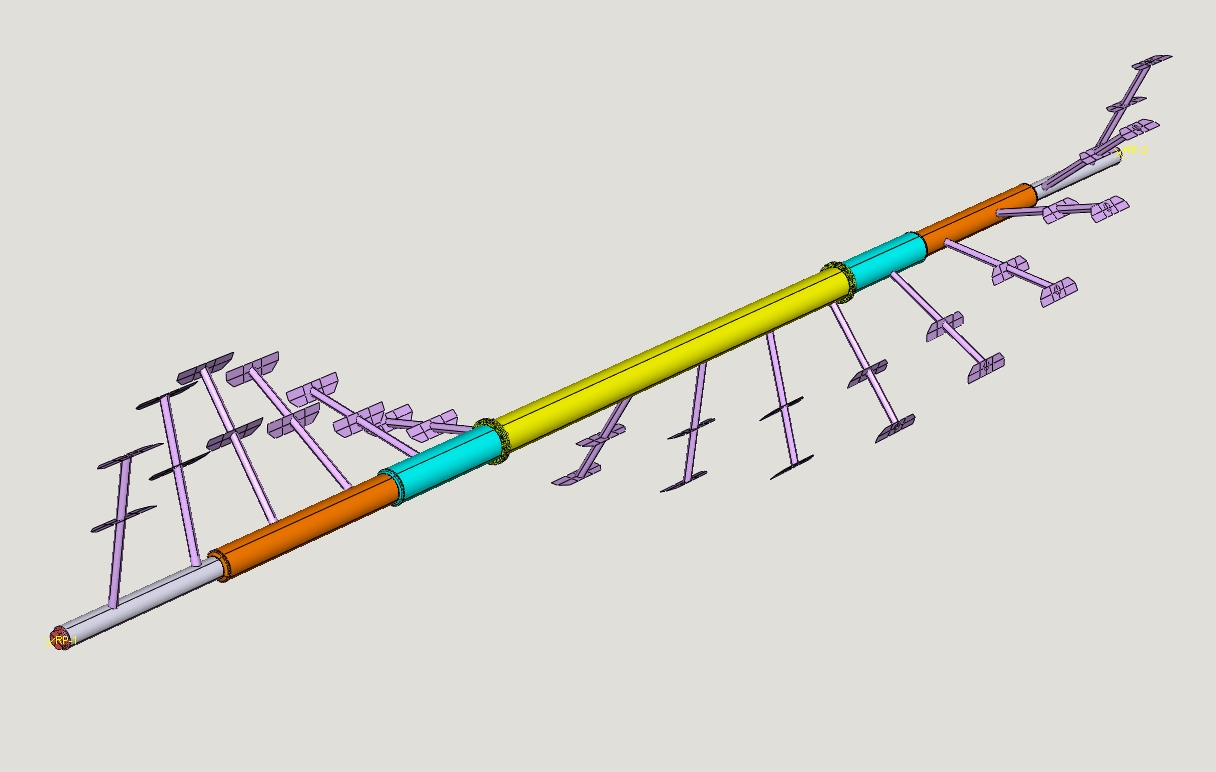

This project centered around the failure of the stirring axis within an organic waste mixing installation designed for biogas production. The stirring axis, measuring approximately 30 meters, is propelled by a 30 kW engine, rotating at 2 revolutions per minute, and is outfitted with 16 paddles. Given its considerable length, the axis is constructed from different segments interconnected through bolted flanges. Unfortunately, after just a few years of operation, one of these flanged connections experienced bolt shear failure. Our assignment was to investigate and elucidate the root cause of this failure.

APPROACH

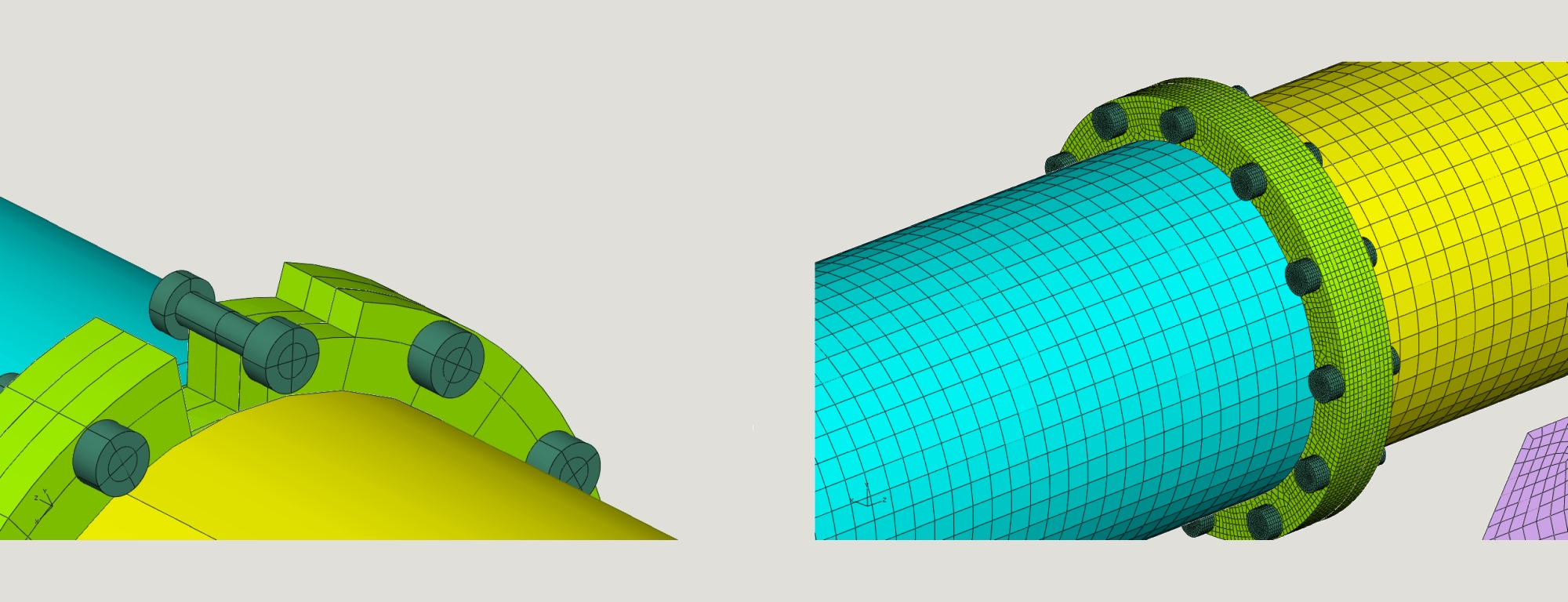

In the initial phase, we constructed a comprehensive 3D model of the stirring axis, with special attention given to the flanged connections. Notably, the bolts were modeled as 3D geometries, and specific contact conditions were defined between the bolts and flanges. The model also incorporated the pre-tensioning of the bolts.

Following the creation of the model, various operational scenarios were identified collaboratively with the customer. These scenarios encompassed potential events in daily operations, such as the obstruction of a paddle due to solid waste, the accumulation of denser sludge at the mixer's bottom causing additional torsion in the shaft, vibrations, and more.

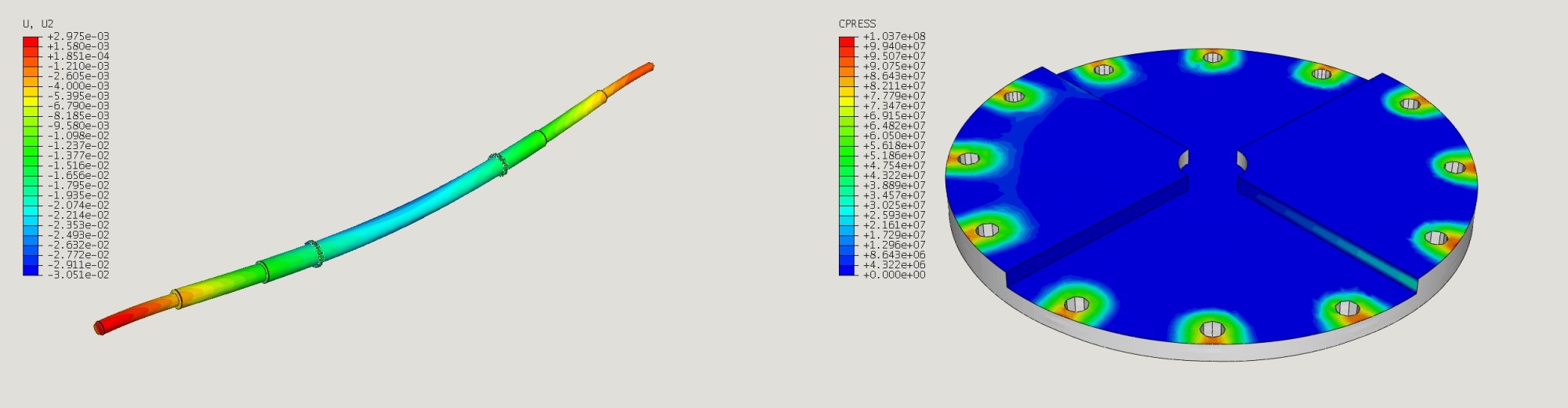

Analyzing these load cases provided stress ranges on the bolted connections, which were then evaluated under both static and fatigue conditions. Surprisingly, based on these calculations and the assumed conditions, the flanged connections were expected to withstand the operational loads without failure.

However, two alternative explanations were proposed. The first involved inadequate pre-tensioning of the bolts, which, under certain scenarios, was demonstrated to lead to shearing of the bolts and subsequent failure of the flanged connection. The second possibility considered an unaccounted-for load case (which could not be verified obviously). Thorough investigation revealed that insufficient pre-tensioning could indeed cause the connection to fail.

RESULT

These simulations offer a plausible explanation for the observed failure, although it does not inherently serve as definitive proof and remains subject to some degree of uncertainty. To address this, additional considerations were explored concerning the bolted connections. One proposed solution involved the utilization of distinct materials for the flanges and washers, a modification aimed at reducing the likelihood of bolt loosening and potential failure.

3D model of the stirring axis

Detail of one of the bolted flange connections

Deflection of the axis in one scenario involving asymmetric loading (left) and illustration of the contact pressures in the flanged connections (right)