electrowinning

of non-ferrous

metals

SCOPE

Electrowinning cells are essential components in the final steps of refining non-ferrous metals. These cells are highly specialized and customized to the specific needs of each customer, and every design is unique. Copper refineries make up the largest market for these cells, followed by zinc refineries, and they are also used in nickel and cobalt refining.

To withstand the harsh environment within the cell, which involves a sulfuric acid solution at a high temperature, and the high mechanical load of the electrodes, the cells are typically made from polymer concrete. The electrolyte-filled cells contain a series of electrodes where the refined material grows on the anodes. However, given the concrete's exposure to changing environmental conditions, cyclic thermal and mechanical loading, and high electrolyte temperatures of up to 80 degrees Celsius, predicting the long-term behavior of these cells in situ is challenging. They are prone to creep, fatigue, and damage over time, making it a challenge to maintain the geometry and strength that is essential for efficiency.

Together with the manufacturer of the cells, we have been working for years to improve the modeling techniques for these cells, in order to better predict their performance and address any issues that arise.

APPROACH

Our ongoing research aims to improve the design of new electrowinning cells. One area of focus is the calibration of a more advanced material model that can better capture the long-term mechanical behavior of the concrete. The "damaged concrete plasticity" (DCP) model takes into account effects such as damage, permanent deformation, cyclical loads, and more, going beyond simple linear elastic models. This calibration involves numerous tests at different temperatures and time scales, enabling a deeper understanding of the thermal and mechanical behavior of polymer concrete in cells.

The market for electrowinning cells is shifting towards more complex designs, with an increasing demand for appendages cast on the cell, longer and wider cells, and extreme operating conditions such as maximum electrolyte temperature and minimum outside temperatures. Moreover, there is growing interest in the development of jumbo cells that require minimal usage of resin, which makes up a significant portion of the cell's cost. Our research team is constantly studying new ideas and designs to meet these changing demands together with the manufacturer.

RESULT

Ongoing research efforts will continue to improve our understanding of the thermal and mechanical behavior of polymer cells, which will ultimately result in more economical and efficient designs. With the development of advanced material models and increasing knowledge about the long-term behavior of these cells, we can optimize designs to withstand extreme operating conditions and improve the overall performance and cost-effectiveness of electrowinning processes.

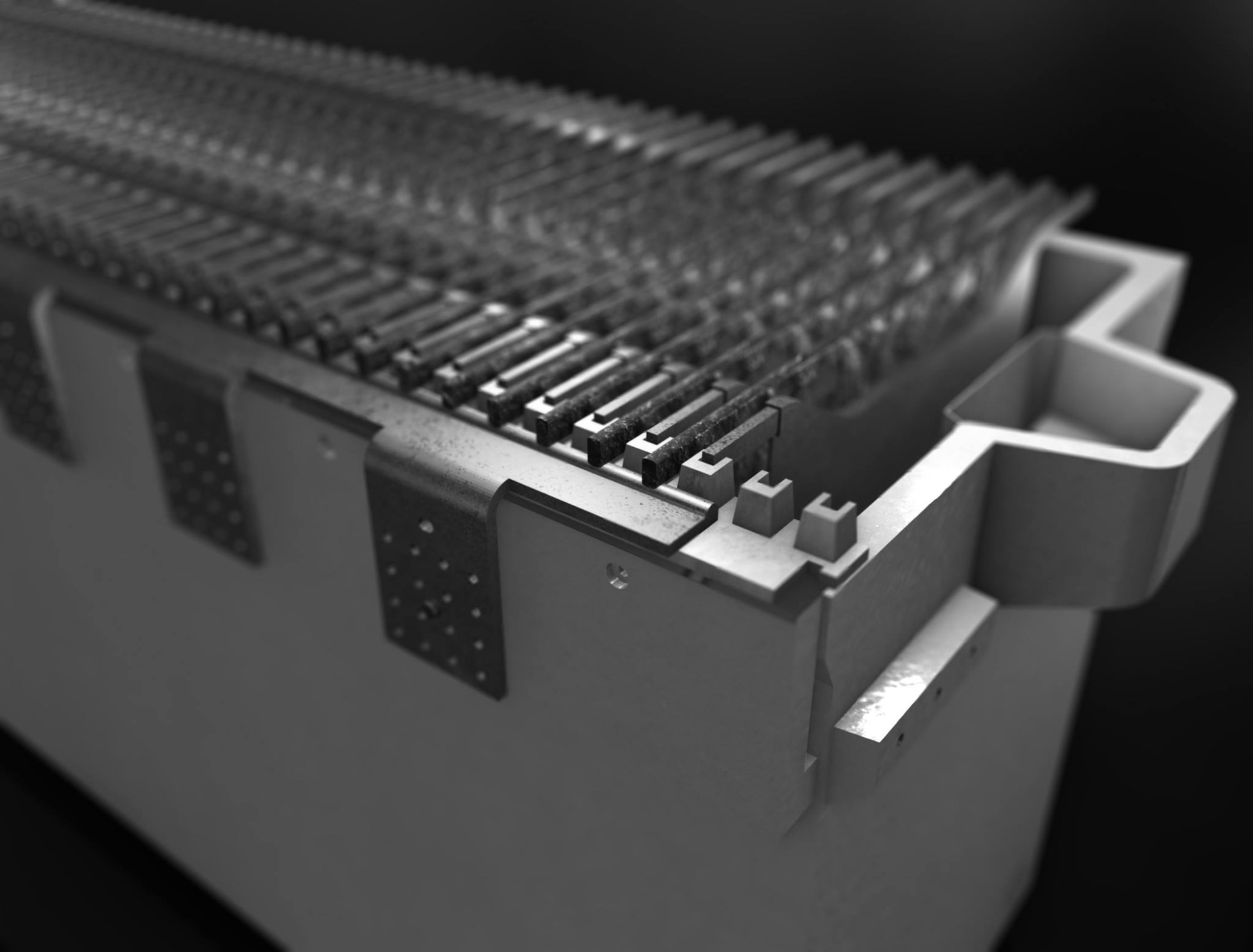

3D rendering of an electrowinning cell

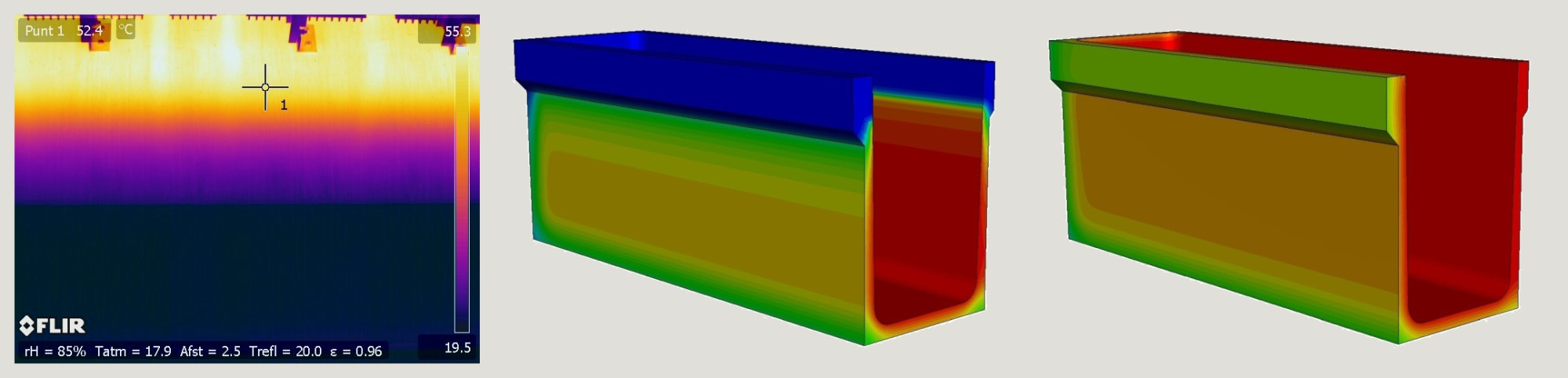

Thermal imaging of a cell in operation (left) and simulation of the transient thermal behaviour of the filling of a copper cell

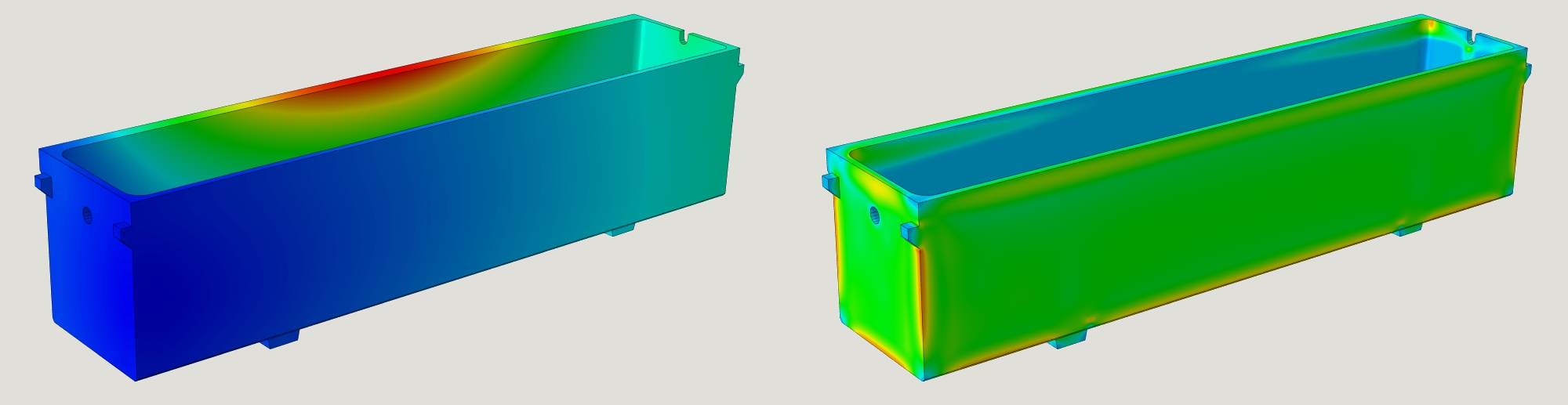

Deflection and stress distribution in a copper cell during steady-state operational conditions