drop testing

of ketchup

filled cups

SCOPE

Many people who have eaten a hamburger at a fast food restaurant are familiar with the small plastic cups that hold ketchup, mayonnaise, or other condiments. However, a significant proportion of these cups are damaged during transportation and handling, rendering them unfit for consumption. Typically, these cups are packed in large cardboard boxes, with 10 cups stacked on top of each other. When these boxes are moved or transported, an impact load is often transmitted to the cups, causing the weight of the cups in the lower rows to increase and resulting in failure. As a result, the lid, which is glued to the cup, often becomes partially detached, leading to spills of ketchup.

The objective of this study was twofold: firstly, to create a simulation model that would yield a deeper understanding of the cups' behavior during a drop test; and secondly, to explore ways to enhance the adhesion between the lid and the cup.

APPROACH

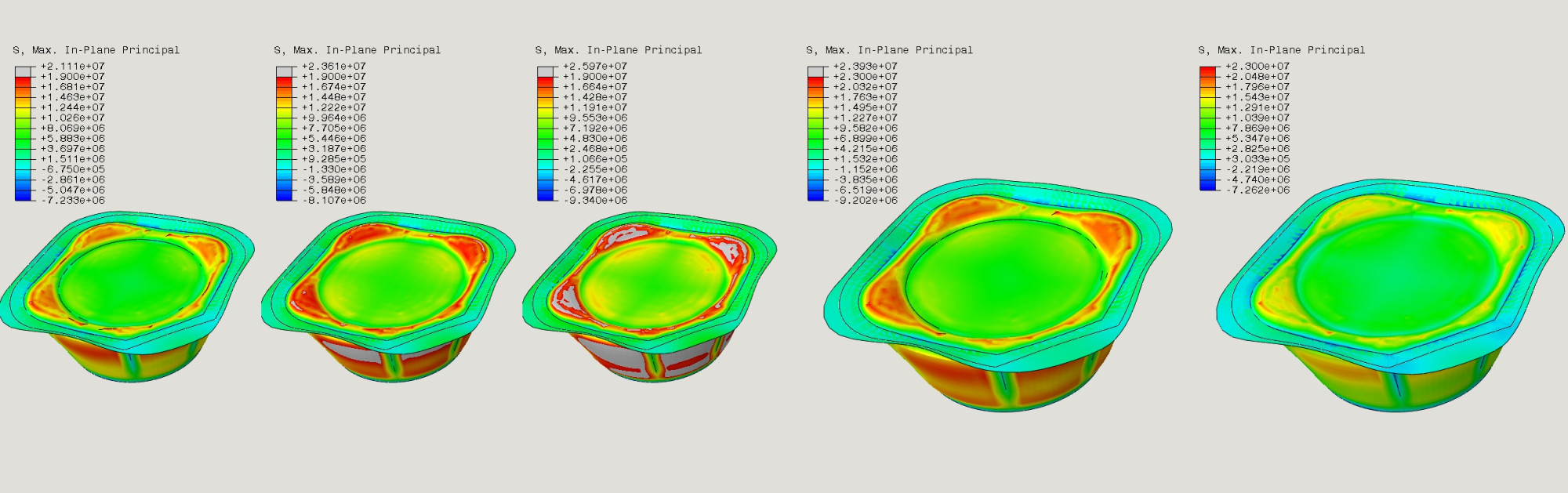

In the first stage of the study, a series of compression tests were carried out on two cups that were placed between two plates and compressed together. The resulting force-displacement curves were used to correlate a finite element model of the cups. An inverse method was employed to determine the material properties of the ketchup using an equation of state, as well as to establish a suitable failure criterion for the glue based on the maximum principle stresses.

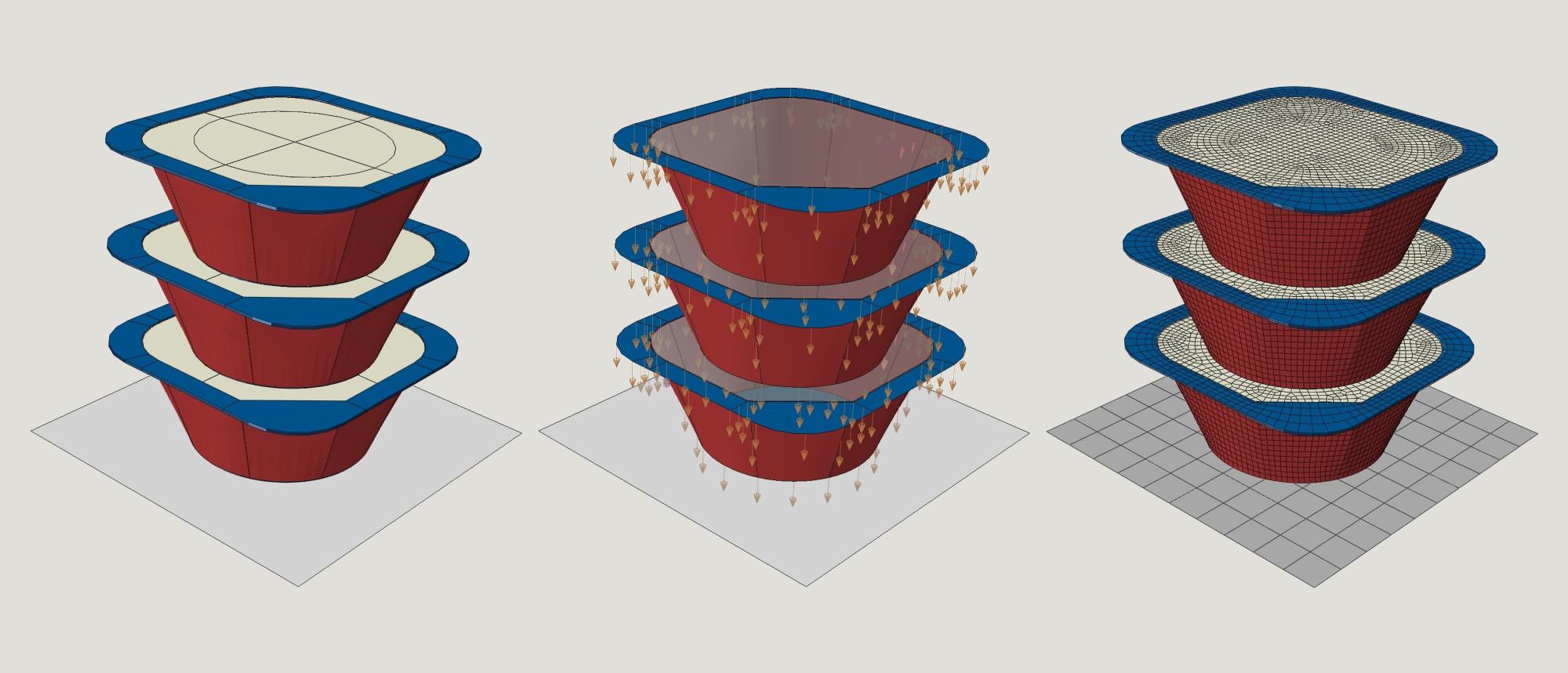

Subsequently, a simulation model of the drop test was developed, wherein the problem was simplified to a single column of ten cups stacked on top of one another. Due to the presence of fluid-structure interaction, a dynamic explicit analysis was conducted using the Coupled Eulerian-Lagrangian (CEL) technique. This led to the creation of a highly detailed model consisting of over 1.5 million degrees-of-freedom.

RESULTS

After the material properties were calibrated, the study confirmed that the glued lid-cup interface is susceptible to failure when a certain drop height is exceeded. To improve this, different types of glues with higher bond capacity were considered along with changes in the distribution of the glue interface. The theoretical maximum drop height without failure could be increased by almost double, resulting in a significant reduction in the number of cups failing during transportation and handling.

Simulation setup for the drop test

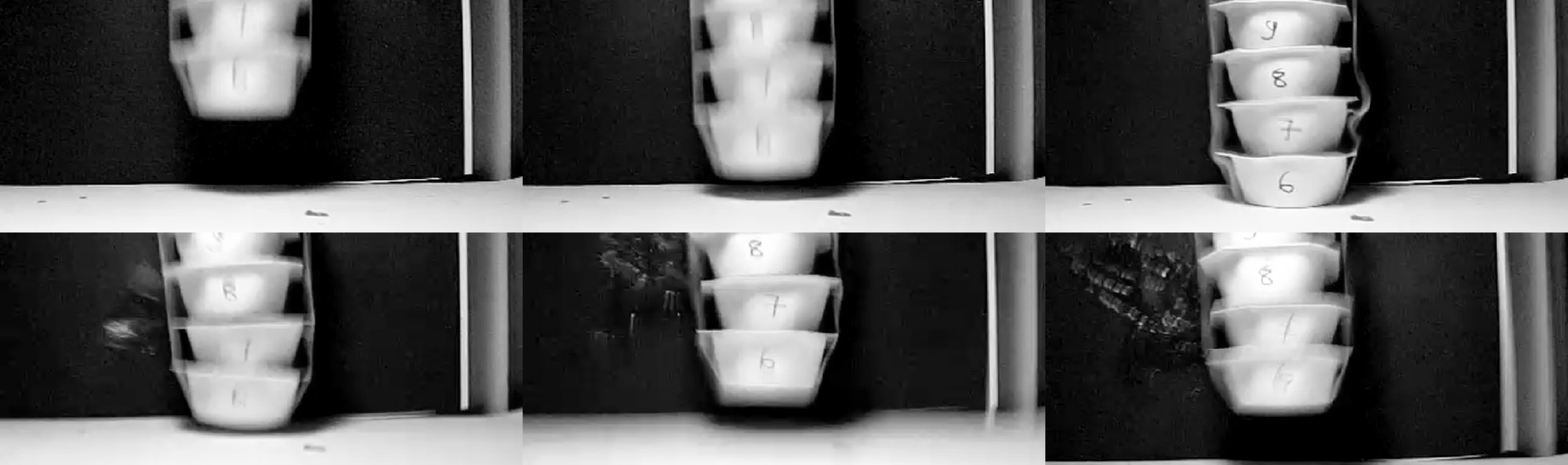

Screen captures from a drop test

Typical FE results showing the tensile stresses in the lid