impact of a

maintenance

gondola

SCOPE

A gondola serves as a lifting system designed for the maintenance of building facades, particularly for tasks like window cleaning. In this particular project, the gondola is designed to accommodate two operators and is powered by a crane. Typically, the movement of the gondola is carefully guided to avoid contact with the building, often facilitated by profiles mounted on the facade. However, in this specific instance, this conventional approach was impractical due to the installation of aluminum sunscreens on the facade.

The presence of these sunscreens, coupled with the absence of a guiding system, introduces the potential risk of the gondola colliding with them. The primary objective of this study was to optimize both the sunscreens and the gondola to proactively mitigate any potential damage. Additionally, specific usage conditions have been outlined, particularly concerning the maximum wind load permissible for the safe operation of the gondola.

APPROACH

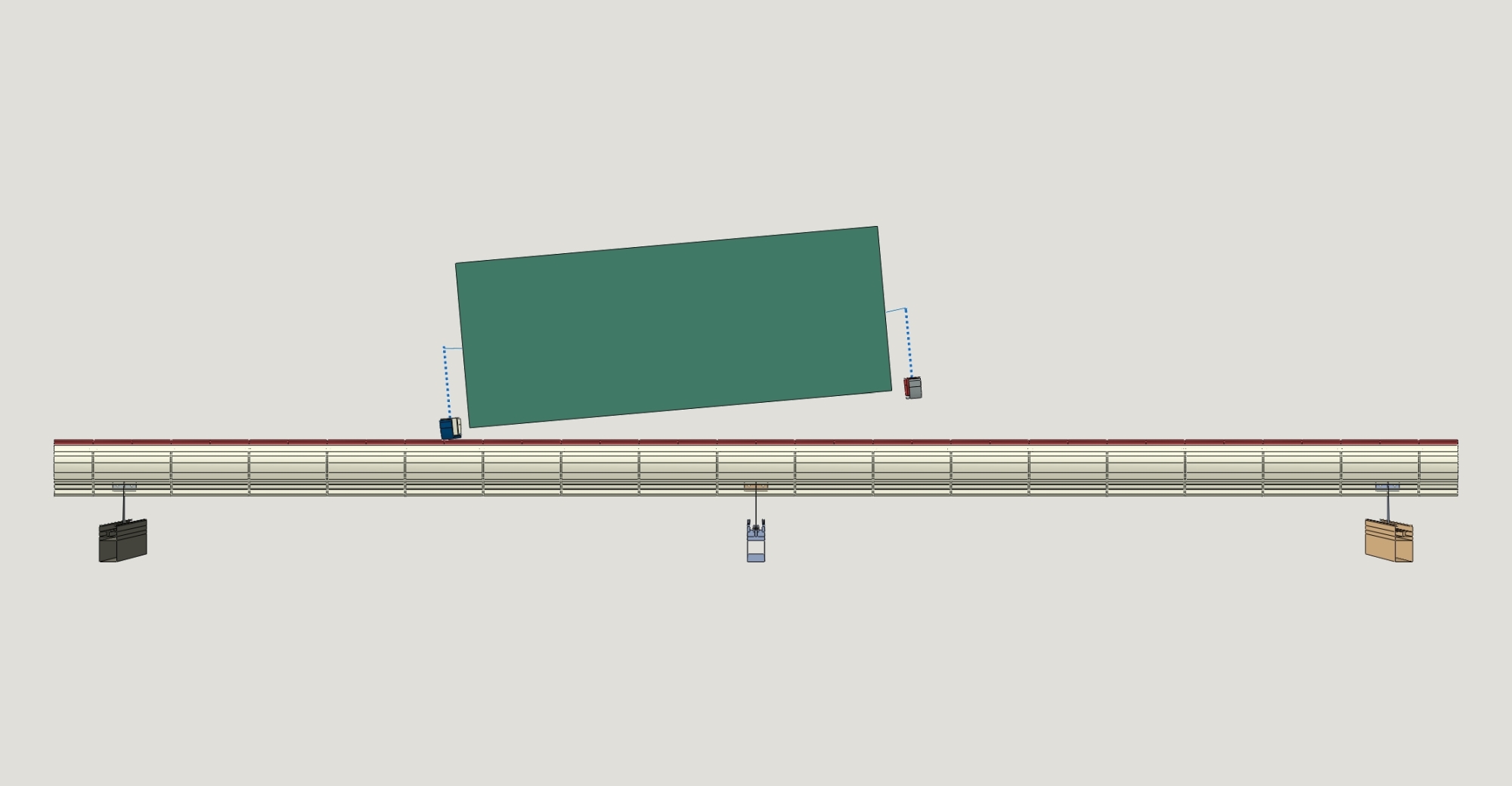

An agreement was reached with the customer stipulating that the gondola would only operate within the constraints of a maximum wind speed of 4 on the Beaufort scale, corresponding to a 3-second gust wind of 12.3 m/s at a maximum height of 50 meters. In a conservative approach, it was assumed that the gondola's impact would be on a single sunscreen element and that the gondola would tilt upon impact, resulting in a single initial point of contact. The total mass of the gondola was estimated at 390 kg. This mass, when combined with a suction wind pressure, resulted in a maximum (swinging) speed of 2.3 m/s, considering a cable length of 26 meters.

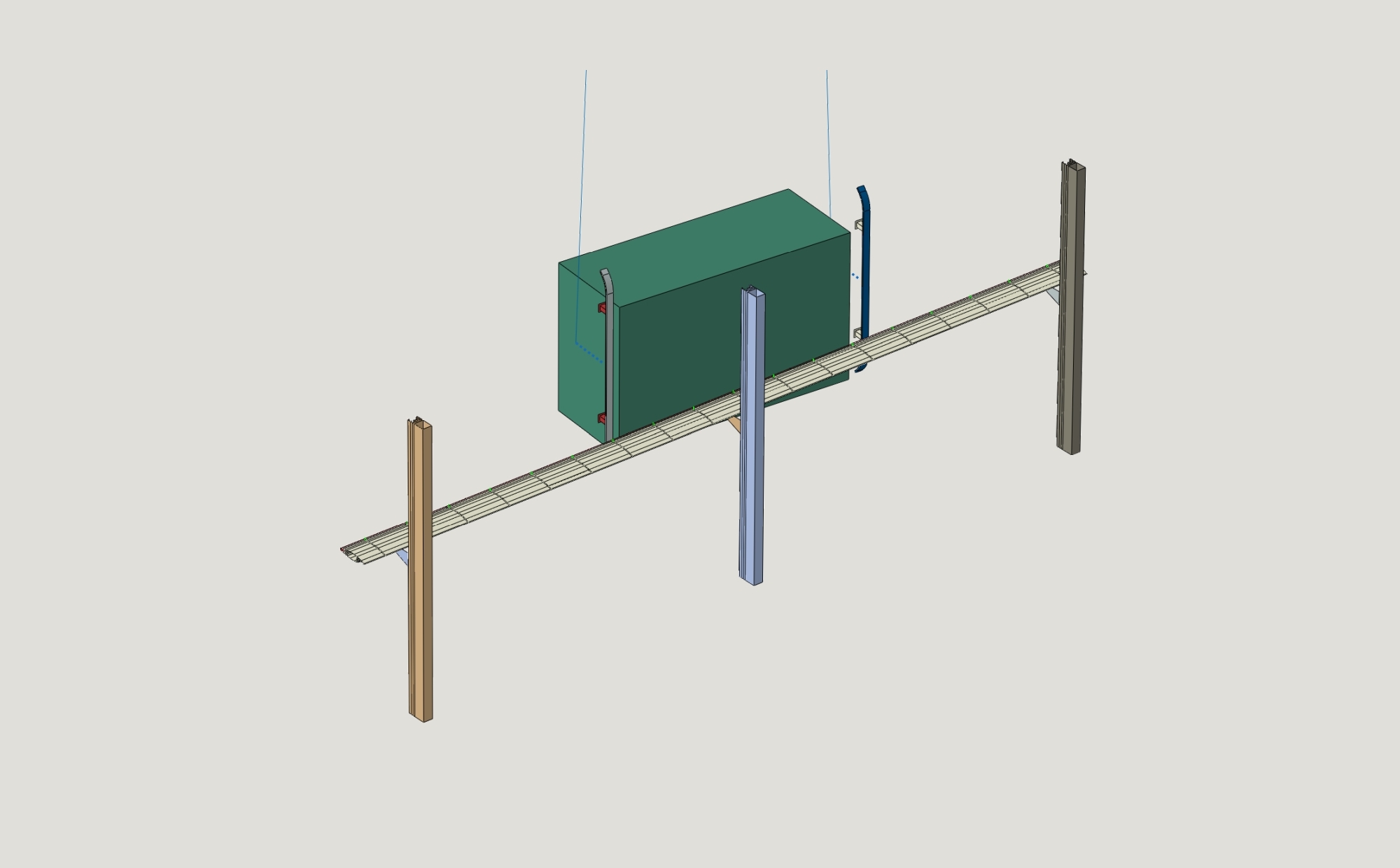

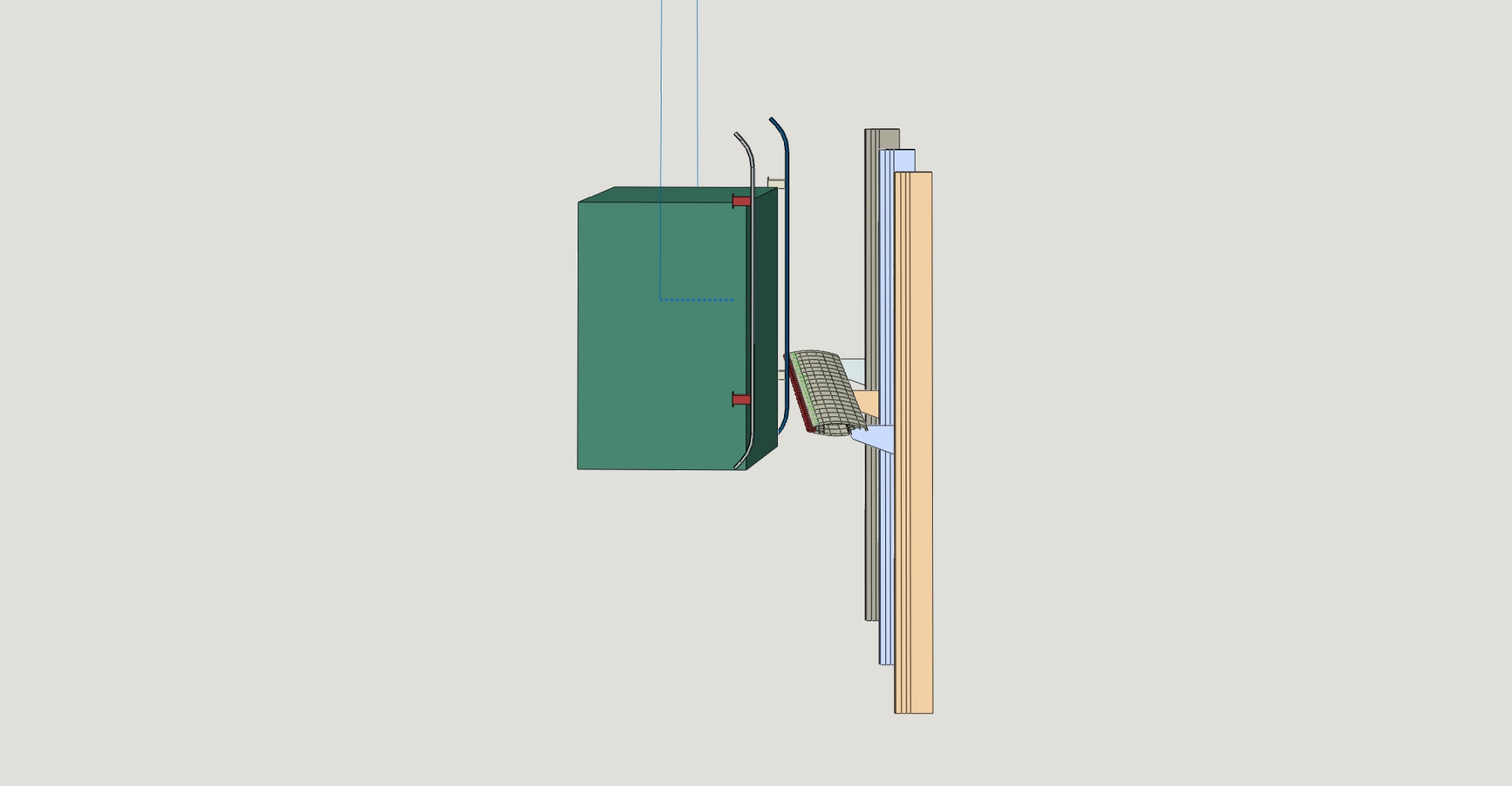

In terms of the 3D model, a single sunscreen profile, 6 meters in length, was created. It was connected to three vertical profiles using blades, with a blade-to-blade distance of 2.7 meters and a vertical profile length of 2.1 meters. Most components were modeled as shells, except for the gondola, rubber blocks, and Teflon strips; cables were modeled as truss elements. The skis, equipped with Teflon strips and blocks to absorb impact, were connected to the gondola using a combination of linked reference points and connectors.

Implicit dynamic procedures were employed for simulations, allowing most components to deform plastically locally within defined limits. The main profile and vertical facade profiles were constructed from EN AW 6060 T5, while the skis and blades were made from SS304. Both materials used an elastoplastic material model with strain hardening. The Teflon strips and blocks, responsible for absorbing impact, were modeled using a 3rd order Ogden hyperelastic model. The entire setup underwent assessment following Eurocode standards.

RESULT

Following the initial simulations, the design underwent extensive optimization, incorporating various enhancements. These improvements encompassed the addition of extra shock absorbers on the skis, adjustments to several geometric dimensions of the skis, inserts, and blades, as well as modifications to the cross-sectional profile of the vertical profiles. The outcome of these refinements resulted in a substantial reduction of the initial maximum plastic strain in critical components, decreasing from 0.13 to an acceptable level of 0.002. Notably, the maximum impact force on the blades experienced a significant reduction of almost 50%.

Overall view of the 3D model

Top view at the moment of impact

Side view at the moment of impact