giant aluminium

roof

SCOPE

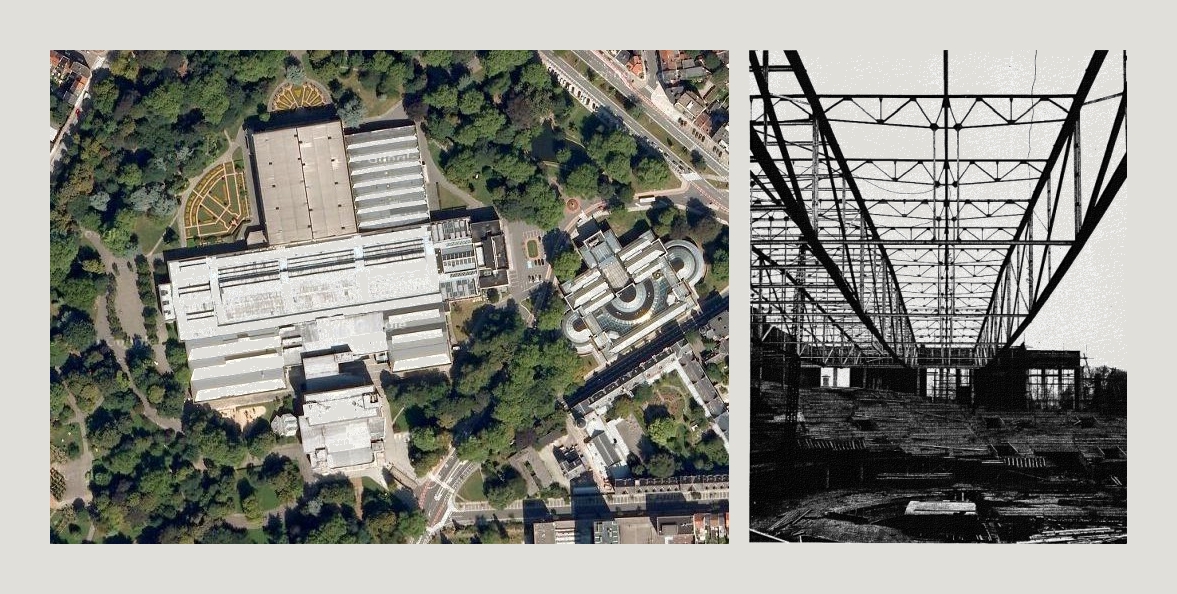

The "Kuipke" is a unique wooden cycling track that boasts steep edges measuring 52°, surrounded by stands capable of seating up to 5,000 spectators. The track is 166.66 meters long and is located in a rectangular hall under a flat roof, which is centrally built against the north facade of the Festivities and Floralies Palace in Ghent. Situated in the tranquil green surroundings of the Citadel Park, the Kuipke is an iconic landmark of the city.

Unfortunately, a fire destroyed the original Kuipke on November 12, 1962. In response, a new Kuipke with a full aluminum roof was built and opened in 1965. This new structure, measuring 86 by 68 meters, is still one of the largest aluminum roofs in Belgium today.

As part of our project, we were tasked with assessing the roof's structural capacity according to modern building standards. Our objective was to determine whether additional (hanging) loads could be safely introduced to the roof.

APPROACH

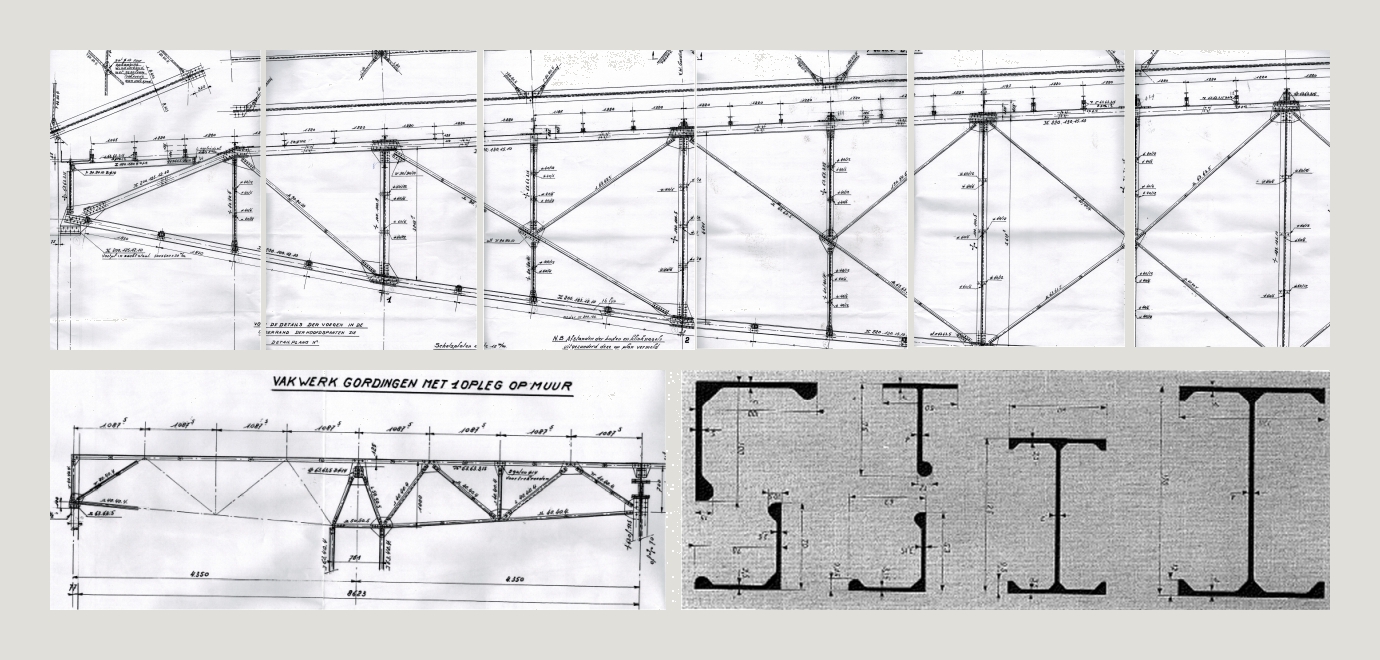

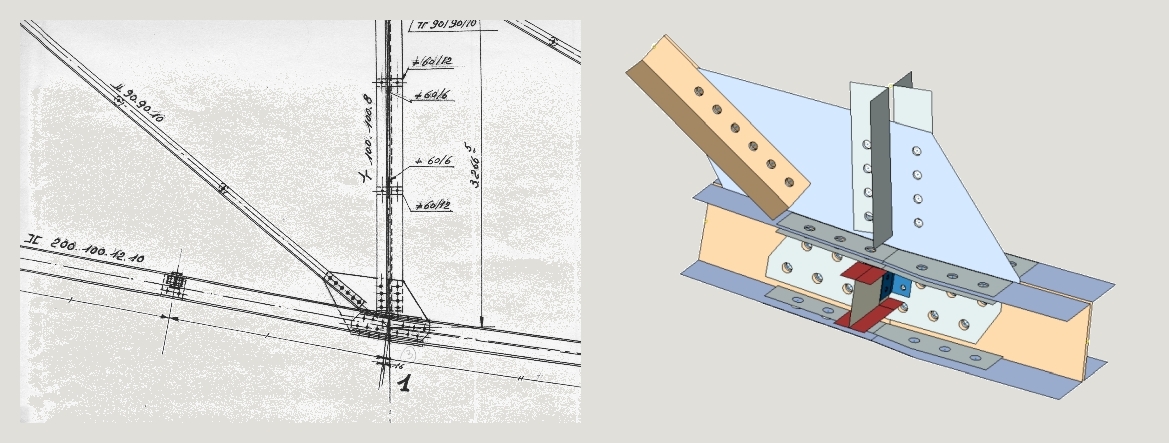

We began our project by constructing a complete 3D model of the roof in Scia Engineer, based on the original drawings. The aluminum profiles used in the roof's construction were "steel-looking" profiles, including L, T, and I beams, and featured additional buckling provisions. The majority of connections were realized using riveted gusset plates. In total, 26 types of aluminum profiles, weighing a total of 125 tons, were used. The aluminum profiles were made from a grade equivalent to today's 6082 T2, while the rivets were made from A-G5.

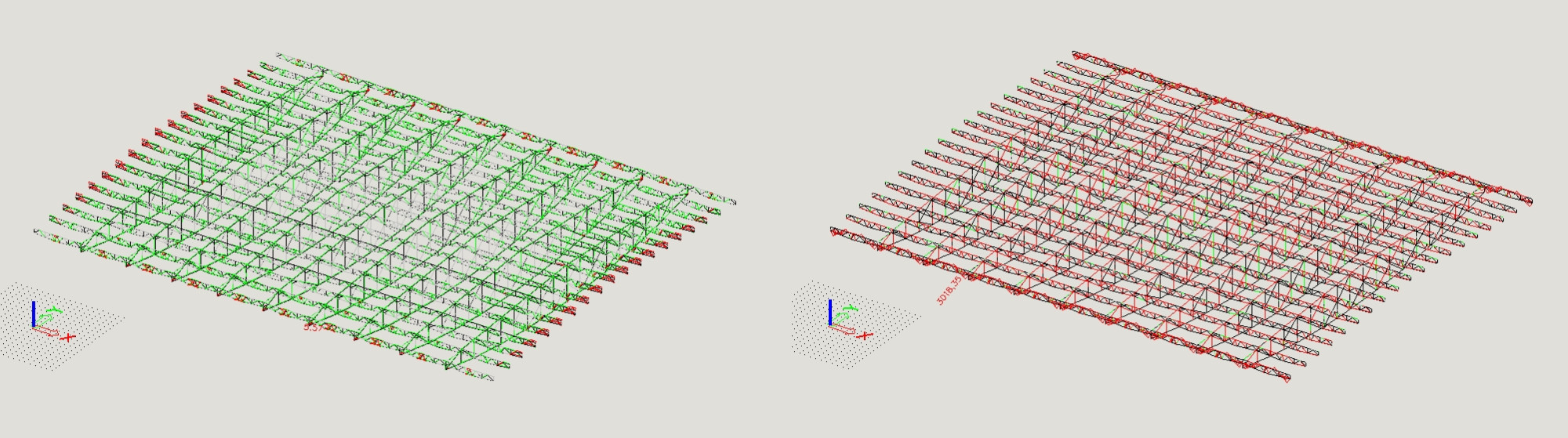

Back in the 1960s, before the introduction of Eurocode, the roof was calculated by hand to withstand a combined wind and snow load of 50 kg/m2, with a safety factor of 3 applied to the tensile strength of the materials. Using the old load assumptions, we conducted a first simulation and confirmed that the roof was still structurally sound.

However, with our current understanding of wind loading, modern-day standards require us to take into account a reference peak wind pressure of 92 kg/m2 for this specific roof, with different pressure zones on the roof, combined with a snow load of 40 kg/m2. When recalculated according to Eurocode, the roof's structural capacity changed significantly.

RESULT

After conducting a sectional check of the roof in accordance with modern-day standards, we found that the roof's structural integrity was still acceptable. However, when we performed a buckling verification, we determined that it was not possible to safely suspend weights from the roof. Despite this limitation, we were able to confirm that the connections were still strong enough to withstand loads according to modern-day standards.

Some of the original drawings of the roof structure

Original drawing and 3D FE model of one of the connections

Sectional and buckling check of the roof structure according to modern standards